Activated Biochar engineered using a specific methodology tuned to each feedstock.

Biogas Plants Face Many Challenges:

↘︎ Low methane yield

↖︎ High costs of feedstocks

⚡︎ High or spiking VFA levels

⚠︎ Ammonia and nitrogen spikes

⚠︎ Foaming

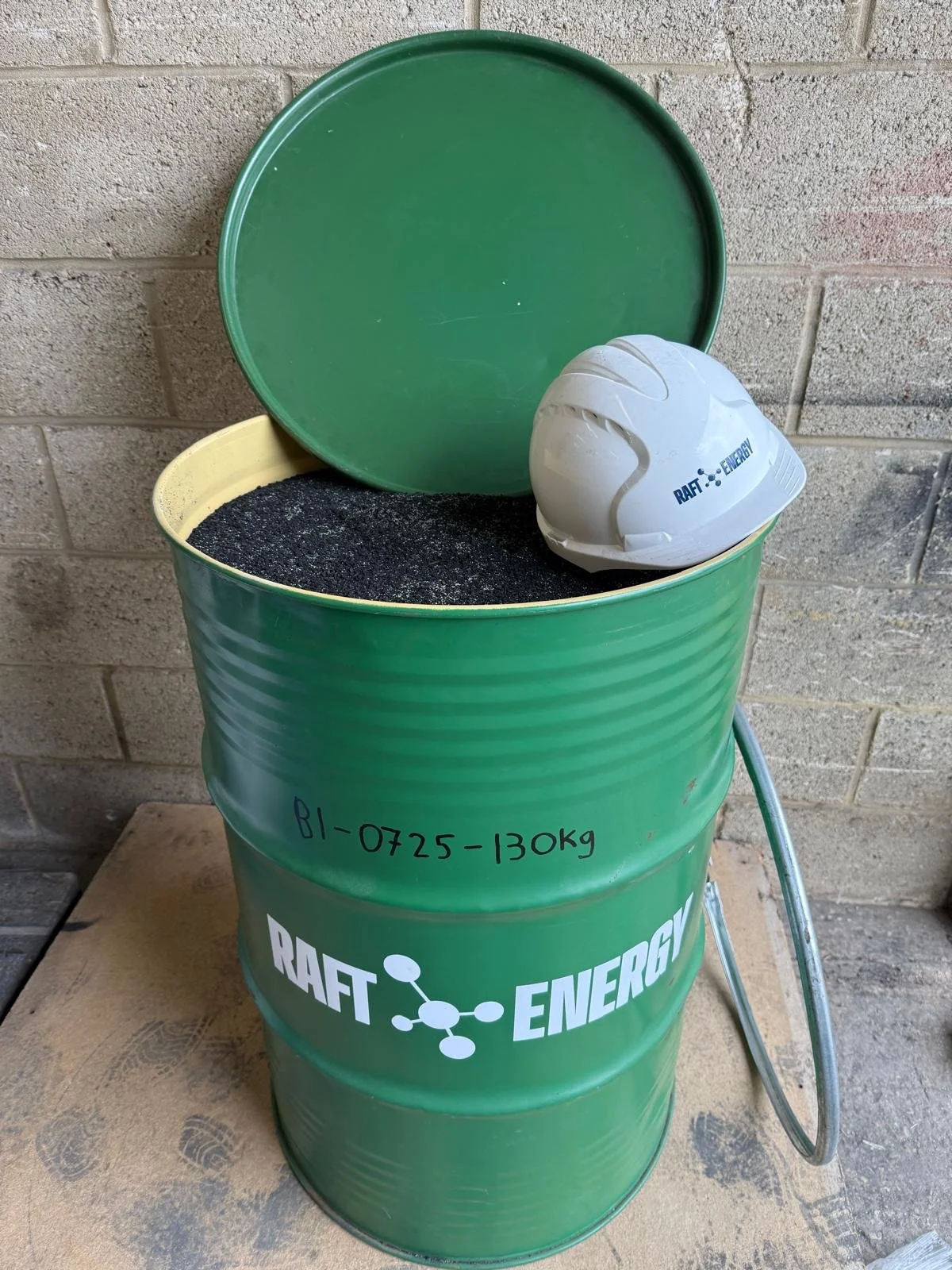

ActiCH4R™ in production at our UK facility

Benefits

-

(*depending on conditions)

Gas-to-Grid plants reduce costs for gas upgrading

-

-

Provides a space for optimal microbial reproduction and energy transfer

-

Balances pH, VFAs & ammonia

-

Faster processing, smoother operations

Process

Introduce to daily feed for 7 days

Day 8 loading day: Bring the ratio up to 2.5 grams/l of working volume

Add daily to maintain 2.5 grams/l ratio with daily feed

Does not require temperature or moisture control storage (store inside)

Non-toxic and safe to handle

The ActiCH4R™ in the digestate improves the quality of the fertiliser and is not impacted by pasteurisation

BIOCHAR VS ACTIVATED BIOCHAR:

The benefits of biochar have been discussed in the biogas industry for years…

Not all biochar is equal and there are some low performing biochars on the market.

ActiCH4R™ is a sustainable, organic catalyst created for the biogas industry. It is an aluminosilicate activated biochar engineered using a specific methodology tuned to each feedstock.

Research & Development

We have been in R&D for two years and worked with Concept Life Sciences, Bioclear Earth and the Biorenewables Development Centre at York University.